File photo/NBD

Demand for lithium -- critical to powering sustainable technologies -- is rapidly growing but up to 75% of the world's lithium-rich saltwater sources remain untappable using current methods.

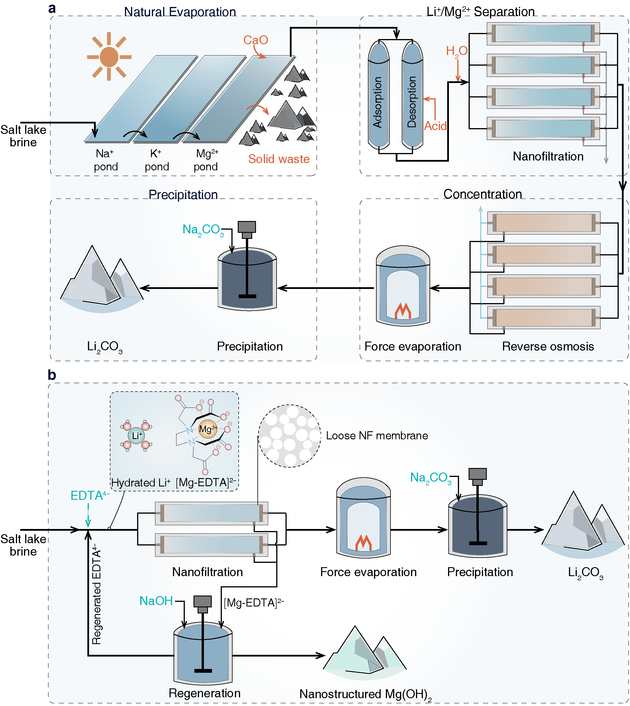

On October 22, the breakthrough in lithium extraction technology was unveiled, causing a stir in the industry. The technology uniquely extracts both lithium and magnesium simultaneously, unlike traditional methods that treat magnesium salts as waste, making it smarter, faster and more sustainable.

The work, co-led by Dr Li Zhikao, from the Monash Suzhou Research Institute and the Department of Chemical and Biological Engineering, and Professor Xiwang Zhang from the University of Queensland, promises to meet the surging demand for lithium and paves the way for more sustainable and efficient extraction practices.

Studies undertaken on brines from China's Longmu Co Lake and Dongtai Lake, published on October 22 in Nature Sustainability, demonstrate how the innovative method could efficiently extract lithium from low-grade brines with high magnesium content.

The news sparked a rally in the A-share lithium extraction sector on October 23. Stocks of companies like Vontron Technology and Jiangsu Jiuwu Hi-Tech saw significant gains, with the latter nearly hitting a 20cm upper limit.

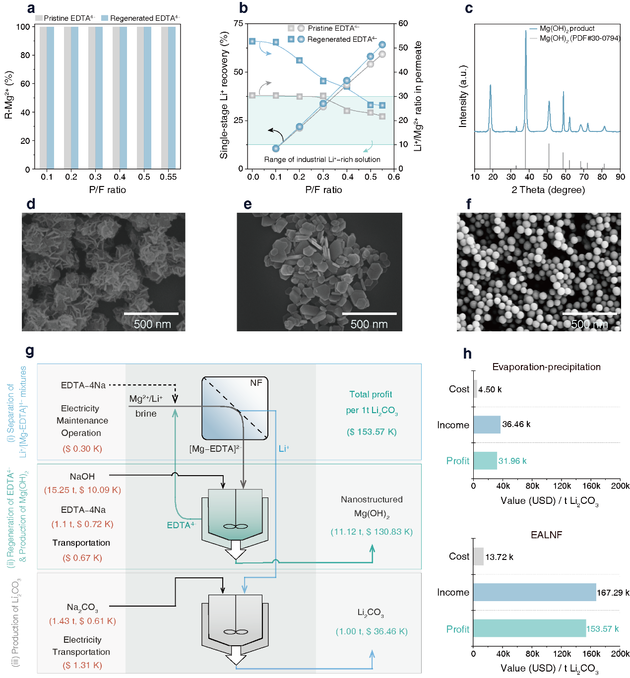

In response to comment request of National Business Daily (NBD), Dr Li Zhikao highlighted that although the results reported in Nature Sustainability were obtained from lab-scale experiments using small-scale apparatuses, the core operation units in the proposed EALNF process have high technology readiness levels (TRL) that have been widely implemented at industrial scales in other applications.

"We are currently seeking funding for pilot and field testing, which are crucial steps toward large-scale applications. Depending on the outcome of these tests, it may take 1-3 years to implement the EALNF process on a large scale." Dr Li noted.

Photo/Nature Sustainability

The EALNF process addresses the strategic importance of lithium resources, which are set to see an 18 to 20-fold increase in global demand by 2050 due to the transformation of energy structures and the growth of the electric vehicle industry. Traditional lithium extraction from brine lakes, which account for 62.6% of global lithium resources, is plagued by long cycles, high magnesium-lithium ratios, large amounts of solid waste, and significant water resource pressure.

Dr Li Zhikao Photo/ Monash University

According to Dr. Li, the new process could dramatically increase the lithium recovery rate from salt lake brines, raising it from the current 30%~50% to 80%~90%. This could effectively double the production of lithium carbonate from the same amount of brine, significantly enhancing output compared to conventional methods.

"Additionally, the process will also convert magnesium salt waste into high-value nanostructured magnesium hydroxide. Depending on market prices, this "byproduct" could make the whole process much more profitable than conventional lithium extraction processes, where magnesium salts are considered waste and cause environmental concerns." Dr. Li added.

The process also reduces freshwater consumption, which is critical in the arid regions where most salt lakes are located. This makes the EALNF process both more sustainable and cost-effective.

Photo/Nature Sustainability

In conclusion, Dr. Li stated that with shorter processing times, less environmental impact, and more efficient use of resources, the EALNF process can better respond to growing global lithium demand, offering a scalable solution to the increasing need for lithium in energy storage technologies.

When asked about the potential for oversupply if EALNF is implemented on a large scale, Dr. Li responded, "as scientists, we may not have access to the latest market data on lithium supply and demand. However, from a scientific standpoint, this technology does not "create" new lithium; it simply enhances the efficiency and sustainability of the extraction process."

Dr. Li further noted, "our primary goal is to minimize the environmental footprint of lithium extraction in the Salt Lake region while supporting the green energy transition. Ultimately, the balance between supply and demand will be shaped by global market dynamics, but our technology can contribute to a more responsible and sustainable approach to lithium production."

川公网安备 51019002001991号

川公网安备 51019002001991号