Jan. 7 (NBD) – The United Nations Intergovernmental Panel on Climate Change (IPCC) released last August their sixth report (AR6) on the Physical Science Basis for climate change, pointing out that under all scenarios examined, the Earth is likely to reach the 1.5°C warming limit in the early 2030s.

The report for the first time speaks with certainty about the total responsibility of human activities that create greenhouse gas emissions for rising temperatures. Thus IPCC calls for countries' actions to cut greenhouse gas emissions to net-zero to cope with the global climate change.

Photo/Shetuwang-500521096

The energy-saving and carbon reduction technologies including Carbon Capture and Storage (CCS) now are widely developed to help enterprises and governments to achieve their goals of cuts in greenhouse gas emissions. CCS refers to the process of capturing carbon dioxide (CO2) from the industrial sources or the atmosphere, transporting it and storing it generally in an underground geological formation.

According to the data released by Irish Market Research Institute research and markets, the global CCS market is expected to reach about 2.8 billion U.S. dollars in 2020 and 4.9 billion U.S. dollars in 2026. As a key part of CCS process, carbon capture can be carried out in many ways, mainly including pre-combustion capture, post-combustion capture and direct air carbon capture (DAC). DAC is considered as the most advanced carbon capture way which draws widespread attention.

How to capture carbon dioxide from the atmosphere? How can the captured carbon dioxide be stored and utilized? When will the CCS technology be deployed at scale? National Business Daily sat down with Stuart Haszeldine, professor of CCS at University of Edinburgh and director of Scottish Carbon Capture and Storage, and Jon Gibbins, professor of CCS at University of Sheffield and director of the UK CCS Research Centre, to discuss about the development and potential of CCS technology.

How can CO2 in the atmosphere be captured?

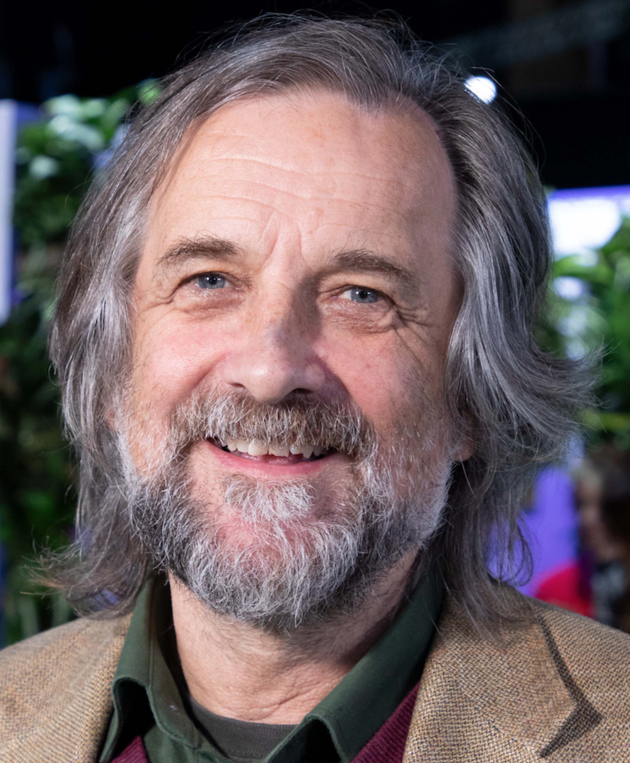

Stuart Haszeldine (Photo provided by the interviewee to NBD)

NBD: Can you introduce the DAC technology and share with us the technology's advantages as compared to other CO2 capture methods?

Stuart Haszeldine: Direct air capture is a group of CO2 capture technologies which is only just starting to emerge. These provide methods of extracting CO2 from normal air, and purifying to 90% or better. The transport and storage part of DAC can be very similar to that of industrial or power plants CCS, but because the DAC can be positioned close to storage sites, then the compression and transport costs may be minimised.

Several different types of DAC are under development including solvent capture over a very large surface areas to contact the atmosphere; solid-state capture where CO2 is adsorbed into porous solids and then able to be released; electrostatic means where by solvents already charged with CO2 can be rejuvenated by short electric charge, which consumes much less energy than heating the solvent. There is great potential for innovation and evolution of new technologies to make this more effective.

An important advantage is that this can be undertaken anywhere in the world where there is a supply of energy and a site for secure storage of CO2. (Also) a market for direct air capture of CO2 can have many customers.

The first are organisations or industries such as hydrocarbon refineries which are required to capture 100% CO2 but are expensive to capture beyond 70-90%-the DAC can recapture the remainder; the second are industries such as major software companies or organisations with computer server farms which emit CO2 or cause CO2 emission indirectly, and these organisations can pay a DAC operator to capture and store CO2 on their behalf; the third might be organisations who wish to acquire CO2 as a feedstock in a circular economy whereby CO2 recaptured from the atmosphere can be remanufactured into methane or hydrocarbon with additional low carbon energy input, and then sold as transport fuel where dense and portable energy storage is needed, the carbon is continually recycled from the atmosphere and not produced from fossil geological resources.

NBD: What are the disadvantages of DAC technology?

Stuart Haszeldine: The supply of energy is necessary to re-condition and recover the chemical solvent which is normally used in direct air capture processes. Compared to carbon capture and storage on power plant or on industry applications, the DAC will require more energy, because the CO2 in the air is much more dilute than flue gas or industrial waste gas.

The significant challenge for DAC is to undertake the capture and recovery of the capture solvent using minimum energy, or very low cost and low carbon energy because any carbon used as fuel to make the heat - will also require to be captured.

Is carbon storage safe?

Photo/Shetuwang-500500094

NBD: How is captured carbon dioxide stored?

Stuart Haszeldine: Carbon storage, not including CO2 separation and purification, already exists in many applications worldwide. There are many natural settings where carbon dioxide from volcanic activity has been naturally contained in porous sedimentary rocks and kept as a secure gas store for millions and even many tens of millions of years. This clearly shows that CO2 storage can be extremely secure and very long lasting.

Geological CO2 storage is one of the most secure and easy to monitor methods of long duration CO2 storage to reduce climate change.

Industrial storage of CO2 has been undertaken since 1972 for the purposes of enhanced oil recovery. The CO2 obtained from natural or industrial sources can be pipelined to oilfields where there are shortages of water or where oil is a very low viscosity. That injection of CO2 can produce large percentages of additional oil, if planned correctly CO2 injected can be greater than the additional carbon produced.

Many publications have examined the security of CO2 storage. Our research group in Edinburgh has also compiled the available data on CO2 leakage from natural and engineered storage to find that 98% of CO2 injected will remain stored for 10,000 years into the future.

NBD: What are the major technical challenges for carbon storage?

Stuart Haszeldine: A basic problem for CO2 storage is not the technology or the monitoring which is very well understood and can be readily adapted from oil and gas technology, but the explanation that this is working and has worked for 50 years still needs to be communicated to the public and to policymakers and politicians and bank investors.

Fortunately there are many examples of small-scale and large-scale tests worldwide including in China, where secure storage has been demonstrated. There are also more than 100 projects in the world where oil is recovered by injection of CO2 and that CO2 remains securely stored underground. And there are more than 20 projects worldwide where CO2 is injected for storage and environmental remediation against climate change and that CO2 also remains securely stored.

Jon Gibbins: Geological storage of CO2 is well-understood technically and relatively mature. The main challenge is the inevitable uncertainty, because rocks kilometres underground cannot be fully characterised, with regards to how much CO2 a particular site can store and how rapidly the CO2 can be injected. There is good confidence in avoiding leakage of CO2 though, since most sites have multiple sealing barriers.

Running smaller number of giant CCS facilities more cost-efficient?

Photo/Shetuwang-500748889

NBD: For carbon capture and storage facilities, some held it is more cost-efficient to operate a smaller number of giant plants than millions of small devices. Do you agree?

Stuart Haszeldine: Where very large sources of CO2 are available, totalling several million tonnes per year, then it is certainly true that the cost per ton of CO2 transported and stored will be greatly reduced if large pipelines are built and shared, and if large capture facilities are built to separate carbon dioxide from large industrial facilities in oil refineries, power plants, or hydrogen manufacture. Because several capture processes rely on heating effects, then there are thermal economies of scale to work with large equipment. But of course very large equipment has a downside meaning very large expenditure long construction time, and inflexible operation.

It is also clear that for some applications, then small-scale CO2 separation has already been built and is operated commercially. Examples include pressure swing adsorption to separate clean gases for greater than 99% hydrogen purity; or simple water wash techniques to separate CO2 fermentation and alcohol making industrial process. These can work at size scales of tends to thousands of tonnes per year, not millions. Consequently, it is important that the chemical engineers understand the requirements for purity and efficiency, not just large-size amine capture and thermal regeneration

Jon Gibbins: Larger plants are more cost-efficient for some purposes and smaller plants for others. We can, and will, have both.

NBD: How can CCS plants capture and store far more carbon than they release?

Stuart Haszeldine: Direct air capture equipment has its objective for the capture and purification of CO2 from dilute quantities in air (0.04%), and industrial CO2 capture has the easier task of separating CO2 from more concentrated mixtures (4-15%). Both of these can be undertaken by choosing chemical solvents which have a strong attraction for CO2, and so can select and hold onto the CO2 molecules from all the other molecules present. That holding of CO2 can be released by methods such as heating the solvent, or an electrostatic pulse through the solvent. If the energy input is low carbon, and is low, then the process works effectively.

One criterion for the design and selection of solvents is their ability to reverse the attraction for CO2 with a small energy input.

Jon Gibbins: Of course, any CCS or DAC plant using fossil fuel as a power source will capture virtually all, or indeed 100%, of the fossil CO2 that arises. For DAC plants, any residual CO2 emissions will be much less than the CO2 removed from the air.

How far is CCS from commercialization?

Jon Gibbins (Photo provided by the interviewee to NBD)

NBD: What are the possible ways to drive down costs for CCS?

Stuart Haszeldine: In Europe, large cost reductions of CCS have now been achieved. This is by improving the design and integration of separation equipment – where the cost of the most expensive step, CO2 capture, has decreased by 20-50%. But also and more importantly by combining together the CO2 from many sources in a "cluster" of CO2 emitters in industrial regions. Such regions may be 1 or 50km across–but can share pipeline transport of CO2, compression of CO2 and storage site injection of CO2. Several regions have recognised that it is possible to re-use existing pipelines to transport CO2 cheaply and to inject CO2 for storage in well understood depleted gasfields. Important also is the decrease of technological risk perception, as more CCS complexes have been designed and several have come to operation.

And in countries focused on industry innovation and leadership, the perception of risk to the overall project has decreased–because many different projects supply CO2 from many sources, and the ability to gain access to several operating storage sites, means that failure of one single source to capture, to transport, to storage has become much less probable. So the price required for a commercial project has decreased.

Jon Gibbins: As soon as CCS is deployed at scale and there is the opportunity to learn from previous projects and incorporate that learning in modifications to existing plants and better technology for new plants. Apart from the scale of the industry and natural competition driving down costs, governments can also ensure that the very early plants that get a lot of government subsidy have to transfer knowledge gained widely as a return payment to society and also that they are able to implement improvements to the plants in service.

NBD: In what fields can CCS technology be commercialized?

Stuart Haszeldine: CCS can be commercial wherever there is a buyer for the CO2. That means that many different sources of CO2, with different capture types, with very different CO2 prices are now available. Some markets such as California Clean Fuel Standard can pay more than 100 U.S. dollars per tonne, 45Q in the USA can pay 50 U.S. dollars per tonne, purchasers of Direct Air Capture may pay 300-1,000 U.S. dollars per tonne. Industrial capture in the UK may pay about 80-120 U.S. dollars per tonne for capture to storage and become cheaper for subsequent additional sources.

Jon Gibbins: Any field that uses fossil fuels or emits anthropogenic CO2 or other GHGs–CCS is what puts the "net" into net zero. So just about all human business activities need to think how CCS, in its various forms, can best be employed by them in the future.

Photo/Shetuwang-500500334

NBD: What actions or polices can governments take to support CCS research and projects?

Stuart Haszeldine: It is now time to shift from research and planning to delivery. Governments can now realise that enough information is available to start incentivising and constructing commercial CCS. There can be a progression from low cost sources such as fermentation and fertiliser, to higher cost sources such as blue hydrogen from methane and combustion of methane or coal in power plant.

A recent IEA compilation of costs shows that CCS in China is now the world's lowest–delivering 80 U.S. dollars/MWhr electricity. And in the culmination of 10 years work, a comprehensive study of all coal fuelled power plant in China shows that it is time to change the categorisation of CCS from "alternative technology" to commercialisation. If a policy for grid price of CCS electricity with a subsidy similar to wind power electricity can be created, then 70% plants with CCS on coal power become competitive with gas, and 22-58% become competitive with wind.

Jon Gibbins: The most important thing that governments can do is to support the construction of large-scale CO2 pipeline systems and geological storage sites. This infrastructure is something that is critical for industry but that it is hard for it to build itself – like roads, railways, electricity grid, water, sewage etc. infrastructure.

CCS on large point sources would benefit from some support for early projects and for research that supports improvements in existing technologies, probably more than research for things that are completely new.

For DACCS, the absolutely key policy development is to allow people/individuals to use as much DACCS as they want to capture their CO2 emissions indirectly and to compensate for other GHG emissions, to get full approval for this as avoiding adverse climate consequences provided that it is done properly. This is obviously environmentally sound.

Government can do a bit of funding to help DAC development and regulation (as it did for early renewables) and certainly should facilitate the provisions of CO2 T&S infrastructure.

Email: lansuying@nbd.com.cn

川公网安备 51019002001991号

川公网安备 51019002001991号