On the evening of April 8, IM Motors held a technology launch event, with the IM L6 taking centre stage.

IM Motors is a Chinese premium EV maker backed by Alibaba Group and SAIC Motor.

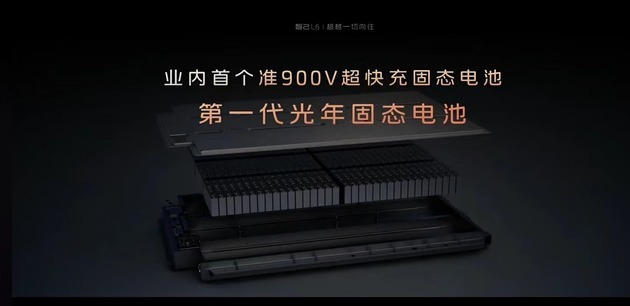

"The IM L6 Max Lightyear Edition is equipped with the first generation of solid-state battery, featured with safety, no battery explosion risk, high energy density and long range," said Liu Tao, co-CEO of IM Motors, at the launch event. With the help of this battery, the L6 is capable of running 1000 KM.

At the same time, Liu Tao also revealed that the pre-sale price of the L6 Max Lightyear Edition will not exceed 330,000 yuan, which sparked widespread discussion.

Photo/WeChat account of IM Motors

“The biggest advantage of solid-state batteries lies in their safety. Since solid-state batteries use solid electrolytes, there is no risk of combustion or explosion associated with liquid electrolytes. Improved safety also allows for an increase in energy density within battery packs, as less space and weight need to be reserved for safety considerations,” said Mo Ke, founder of Real Li Research Institute, also told National Business Daily (NBD).

However, the solid-state battery used by IM Motors is actually a semi-solid-state battery. "(The battery) still uses liquid electrolytes. But in the normal concept, (all) solid-state batteries should no longer use liquid electrolytes." Mo Ke said.

"The controversy surrounding solid-state batteries may be related to their technical challenges and manufacturing difficulties. Currently, what is commonly referred to as “solid-state batteries” is essentially a form of semi-solid-state batteries, with manufacturing processes not significantly different from existing liquid-based systems," said Liu Yanlong, director of business of the China Industrial Association of Power Sources, told NBD.

Because of this, it is widely predicted within the industry that solid-state batteries will only achieve mass production by 2030.

However, according to Liu Tao, even though the “Lightyear” vehicle represents the first generation of solid-state batteries, it achieves nearly 30% more energy capacity with almost the same weight, allowing for a 1000-kilometer range. Liu Tao added, “Our battery can be charged in 12 minutes and provides an additional 400 kilometers of range.”

It’s worth mentioning that the IM L6 Max Lightyear Edition can achieve 900v fast charging. How is this possible?

According to a staff member at IM Motors, the first generation of solid-state batteries of IM Motors was developed through material optimization and patented manufacturing processes. This increased the density of the solid materials, resulting in better ionic conductivity. In simple terms, the overall internal resistance of the battery cell is lower, leading to superior fast-charging performance.

Photo/Press Release screenshot

Setting aside the technological breakthroughs, cost is also a significant barrier to the large-scale implementation of solid-state batteries. Qin Lihong, the president of NIO, once stated during the ET7 semi-solid-state battery test that the cost of a 150kWh solid-state battery pack is close to that of a NIO ET5, which is over 290,000 yuan.

In Mo Ke’s view, the main challenge facing the development of semi-solid-state batteries is how to reduce the cost to an appropriate level. Although there are not many problems with mass production from a technical perspective, the cost of semi-solid-state batteries is still relatively high. If only the electrolyte part is replaced with a solid state, the cost may be 30%~40% higher than that of liquid batteries, or even more.

Solid-state batteries are considered to be the mainstream direction of next-generation battery technology. Although the development of solid-state batteries still needs time, many car companies have already made clear plans for the production of solid-state batteries.

Photo/Provided by IM Motors

Solid-state batteries are considered to be the mainstream direction of next-generation battery technology. Although the development of solid-state batteries still needs time, many car companies have already made clear plans for the production of solid-state batteries.

For example, BMW has promised to launch an electric vehicle prototype equipped with solid-state batteries by 2025 and mass-produce it by 2030. Toyota will mass-produce solid-state batteries in 2027. Volkswagen is actively developing solid-state battery technology and aims to achieve mass production by 2025. NIO plans to mass-produce semi-solid-state battery vehicles in 2025 and plans to equip them on the ET7 model.

According to the latest prediction report of the well-known research institution GGII, 2024 will be an important node for the development of the solid-state battery industry. It is expected that the large-scale loading and application of (semi-) solid-state batteries will be realized within the year, and the total installed capacity for the whole year is expected to historically exceed 5GWh.

川公网安备 51019002001991号

川公网安备 51019002001991号