Prof. Tal Dvir is showing a 3D-printed heart with human tissue at the University of Tel Aviv in Israel, April 15, 2019.(Xinhua/JINI/Gideon Markowicz)

Apr. 19 (NBD) -- A beating, fully-working artificial heart is believed not to be far behind as a 3D-printed heart with blood vessels has come into reality.

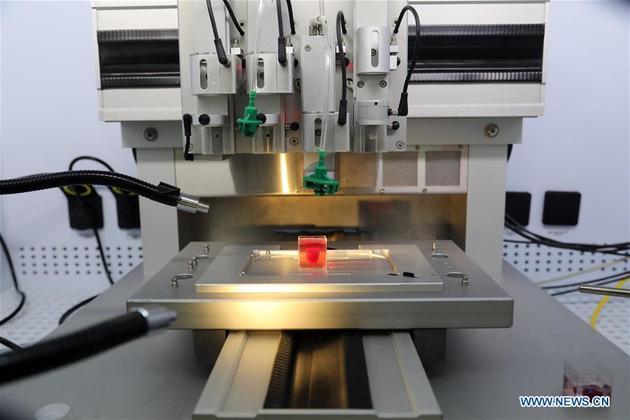

On April 15, standing in the laboratory at Tel Aviv University Israel, professor Tal Dvir was holding a plastic cube clearly displaying a tiny but perfectly-formed heart. The little red thing dominated a huge number of headlines since its debut.

In what the media is calling a "world's first", using a patient's cells, professor Tal Dvir's team successfully engineered and 3D-printed an entire heart replete with cells, blood vessels, ventricles and chambers.

"It's completely biocompatible and matches the patient," professor Tal Dvir said, "The biocompatibility of engineered materials is crucial to eliminating the risk of implant rejection, which jeopardizes the success of such treatments."

This exciting "medical breakthrough" is expected to put the ardurous and dangerous transplantation to an end.

Thrilled as the world is, there are still many puzzles needed to be answered. Engaged in tissue engineering and regenerative medicine, professor Tal Dvir's Laboratory shares their story behind this research and their path forward via the exclusive interview with NBD.

A $150,000 bioprinter, a 6-person team

NBD: When did your team come up with the idea to 3D-print a heart? Could you tell us the story behind the breakthrough research?

Tal Dvir's Laboratory: Our lab specializes in cardiac tissue engineering. The more "conventional" engineered tissues we work on are cellularized "patches" to be placed on the lesion site that is formed following cardiac infarction (heart attack). After obtaining sufficient knowledge in 3D-printing, we thought it would be nice to harness the power of this technology to construct a cellularized complex organ, like the heart, that contains main blood vessels and internal anatomy of the natural organ. This may prove the concept of complex organ engineering.

NBD: How many researchers are there in your team? Are they all working or studying in Tel Aviv University?

Tal Dvir's Laboratory: We are a group of 15 researchers, and 6 of them worked on the 3D-heart printing project. All team members are TAU students and employees. Speaking of our workload, we work about 11 hours a day in the lab, and we also work at home, including reading latest literature, designing experiment, and responding to emails.

The 3D-printed heart with human tissue at the University of Tel Aviv in Israel. (Xinhua/JINI/Gideon Markowicz)

NBD: Your team is the first to 3D-print an entire heart replete with cells, blood vessels, ventricles and chambers. What do you think is your biggest advantage to make you the first?

Tal Dvir's Laboratory: I think it comes from the fact that we are blessed with young and energetic researchers with different fields of knowledge. We are biologists, biomedical engineers and computer scientists. We always search for developments that will combine and benefit from these expertise.

NBD: Could you tell us the size of the money poured into this research? And where did the funding come from? How much did a 3D bioprinter cost?

Tal Dvir's Laboratory: We can say that the hardware, materials and personnel that is required of our research are quite costly. Our 3D bioprinter and its peripherals cost about 150,000 U.S. dollars, but manpower costs much more. And it's the manpower that boosts the research, of course. We got funding from the European Research Council, the Israeli Ministry of Science, the Israeli Science Foundation, and we also received funding from philanthropists in Israel and other countries.

NBD: Is there any expertise needed to operate the 3D bioprinter? If yes, could you shed some light on it?

Tal Dvir's Laboratory: Actually, the printing procedure itself is not very complicated and could be executed by any individual with basic technical skills after a short training. This is, however, not the case for the preparation of the printing materials. These should be extracted by experienced surgeons and professionally tested and processed in the lab. Also, after printing, much laboratory work should be done by experts in the field of tissue engineering in order to mature the tissue.

The 3D-printed heart with human tissue at the University of Tel Aviv in Israel. (Xinhua/JINI/Gideon Markowicz)

3D printing not limited to hearts

NBD: The current 3D-printed heart is only the size of a rabbit's heart, and "larger human hearts require the same technology", you said in the press release. Why is the printed heart much smaller than a human one if there involves the same technology?

Tal Dvir's Laboratory: As this research is a proof-of-concept, we chose to construct small models as they require a relatively small number of cells and less biomaterial is needed to be harvested and processed. Also, the printing time will be much longer to print full size human hearts. The final size of the printed construct is also limited by the hardware (the 3D bioprinter).

NBD: You also mentioned that the printed heart could not beat like a real one now. Your team will carry out the experiment to make it form a pumping ability. What is the biggest difficulty to achieve that significant breakthrough? How long and how much do you think would it cost?

Tal Dvir's Laboratory: The main challenge that we now need to overcome is the long-term cultivation and maturation of the tissues and organs. This step is crucial for obtaining physiological behavior of the engineered structures (In our case – it is the capability of the hearts to contract synchronously and pump blood). We are now investigating these aspects under controlled conditions in the lab-in specialized bioreactors. The bottleneck here is the ability to nourish such a volumetric structure and to "teach" the evolving tissue how to contract synchronously. If we will get positive results, we will move on to transplantation experiments in animal models. Unfortunately, we cannot predict the cost and the time that is needed. It depends on results for experiments that are now being conducted.

NBD: Is there any specific requirement for patients' cells for 3D printing?

Tal Dvir's Laboratory: The procedure itself is generic. No specific requirement from the cells. However, we need to remember that the research is in its infancy and a great deal of R&D needs to be devoted. It is still very far from any clinical application.

NBD: If 3D-printed heart becomes fully working in the future, will the 3D printing technology be applied to print other human organs? If the answer is positive, which organs can be 3D-printed via this technology?

Tal Dvir's Laboratory: As pointed out above, the procedure and the concept is generic. It is not limited to cardiac tissues/hearts. Basically, given the knowledge of how to differentiate induced pluripotent stem cells into cells with specific function, we can think of other tissues and organs that might be printed (in theory, of course) like kidney, liver and lungs. As already stressed, we need to be patient as much work still needs to be done and everything should be empirically tested.

(Special thanks to Mr. Amir Lati, former Israeli consul general to Chengdu for his tremendous support in this report.)

Email: lansuying@nbd.com.cn

川公网安备 51019002001991号

川公网安备 51019002001991号